Jan 23, 2024

Breaking the Automation Pyramid: Why You Should Retire ISA-95

Move past bottlenecked, layered automation stacks. Learn how a Unified Namespace (UNS) enables real-time, scalable industrial data flows.

Ever wondered why a simple temperature sensor value takes weeks to show up in an ERP report?

The usual chain looks like this: PLC engineer exposes the tag, SCADA team maps it, MES consultant pushes it to a database, and finally IT writes a custom ERP query. Each handoff adds meetings, spreadsheets, and scripts. Over time, you end up with the infamous industrial spaghetti of brittle integrations.

The traditional automation pyramid (ISA-95) made sense in the 90s when connectivity was expensive and systems had to be isolated for stability. Today, the same layered structure blocks real‑time operations.

Why the Pyramid Is Collapsing

The automation pyramid was designed to protect systems by keeping them separated. In modern plants it creates three recurring problems:

- Data captivity: Data stays locked inside systems. Every new integration pays an “integration tax.”

- Poor scalability: Adding a new sensor forces updates across the whole stack, slowing innovation.

- Context loss: As data moves upward, it loses meaning. Is “45.2” temperature or pressure? Which asset does it belong to? What’s normal?

The Fix: Unified Namespace (UNS)

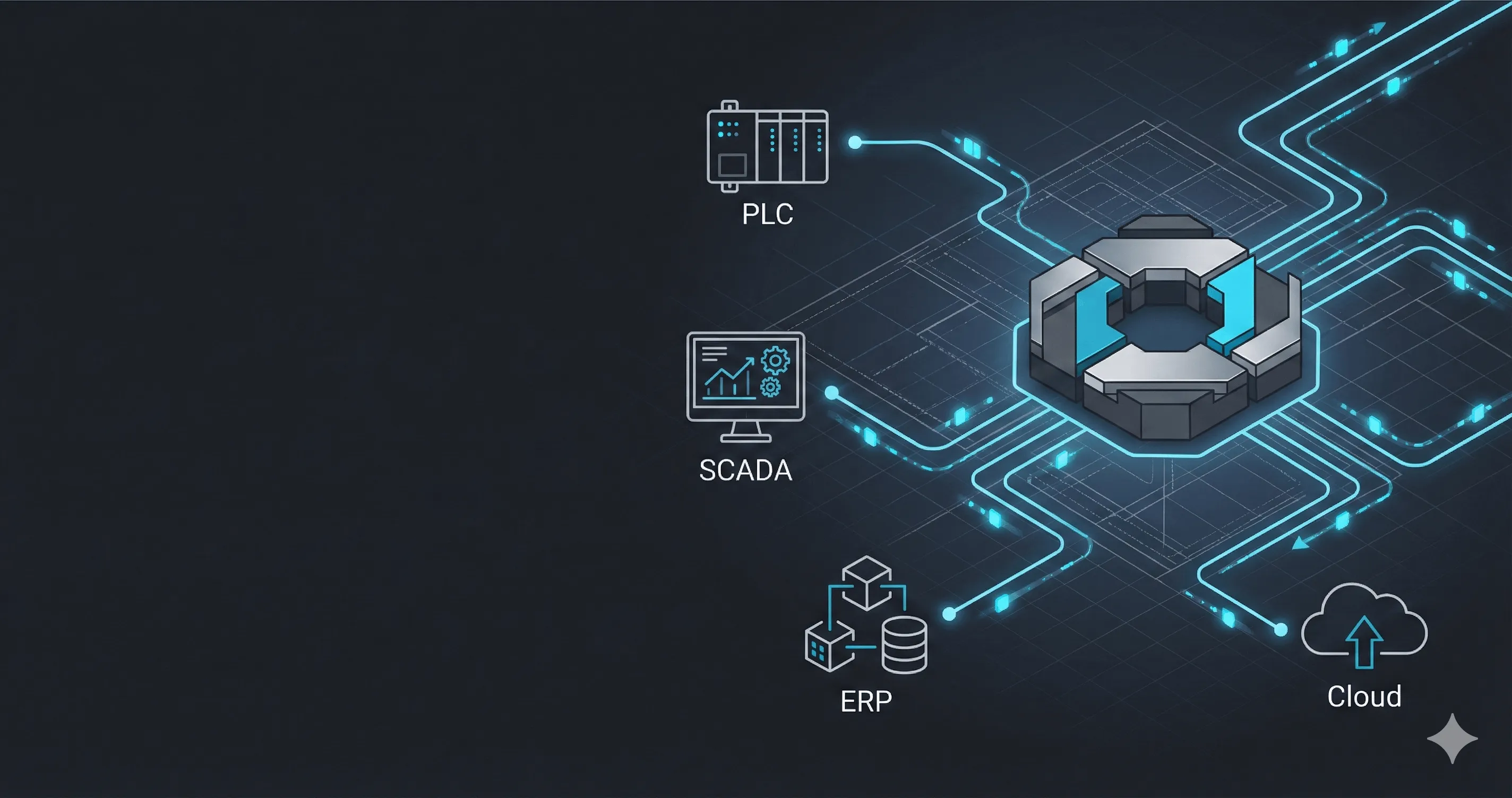

Instead of stacking systems on top of each other, put them side‑by‑side. A Unified Namespace (UNS) is a real‑time data backbone where all systems publish and subscribe to the same shared model.

Think of it like a city square: every system (PLCs, apps, analysts) can publish what it knows and consume what it needs, without bespoke point‑to‑point wiring.

A typical UNS topic model looks like this:

Enterprise / Site / Area / Line / Cell / Asset / Signal

Example:

Proxus / Tekirdag / FillingLine / Machine1 / Temperature

Now every consumer, maintenance tablets, dashboards, AI pipelines, can subscribe to the same live stream at the same time.

MQTT Alone Isn’t Enough

Many “digital transformation” initiatives think installing an MQTT broker is the solution. It isn’t.

Raw data isn’t insight. A PLC sending “1” or “0” at 100 Hz tells you nothing unless it’s contextualized:

- Is the machine running or faulted?

- Is the shift active?

- Which product is in production?

This is where an IIoT platform like Proxus matters. Proxus enriches raw signals with context, manages state, and publishes meaningful information back into the UNS.

How to Start Without Disruption

You don’t need a rip‑and‑replace. Move to a UNS incrementally:

- Start small: Pick a single machine or line.

- Connect in parallel: Listen to existing PLC/SCADA data via a gateway and publish into the UNS.

- Create quick value: Visualize it in a dashboard or report.

- Scale out: Expand once the value is proven.

Breaking the pyramid isn’t just architectural hygiene, it’s how you unlock innovation. Once data is free, everything else accelerates.