Industrial IoT for

Smart Mining

Connect remote sites, mobile fleets, and processing plants into a single digital mine. Optimize crusher throughput, automate weighbridge ticketing, and ensure worker safety in the harshest environments.

Pit-to-Port Visibility

Digitize every step of extraction, processing, and logistics. Review the success story, scorecard, and integration docs.

Crusher & Mill Monitoring

Real-time throughput, power consumption, and jam detection for primary and secondary crushers.

- ✓ Amperage Monitoring

- ✓ Choke Feed Control

- ✓ Wear Prediction

Fleet Management

Cycle time analysis, fuel monitoring, and load counting for haul trucks and excavators.

- ✓ Cycle Times

- ✓ Idle Time Tracking

- ✓ Load Weight

Weighbridge Integration

Automated ticketing and ERP integration for truck scales. Eliminate manual data entry errors.

- ✓ Serial/IP Connection

- ✓ SAP/ERP Sync

- ✓ Fraud Detection

Environmental Safety

Monitor dust (PM10/2.5), gas levels, and vibration/noise for compliance and worker safety.

- ✓ Site-wide Alerts

- ✓ Regulatory Reports

- ✓ Weather Stations

Conveyor Health

Predictive maintenance for rollers, belts, and motors. Avoid catastrophic tear events.

- ✓ Temp & Vibration

- ✓ Belt Speed

- ✓ Misalignment

Water Management

Track water usage, pump health, and tailings dam levels to ensure sustainable operations.

- ✓ Flow Monitoring

- ✓ Leak Detection

- ✓ Pump Control

Success Story

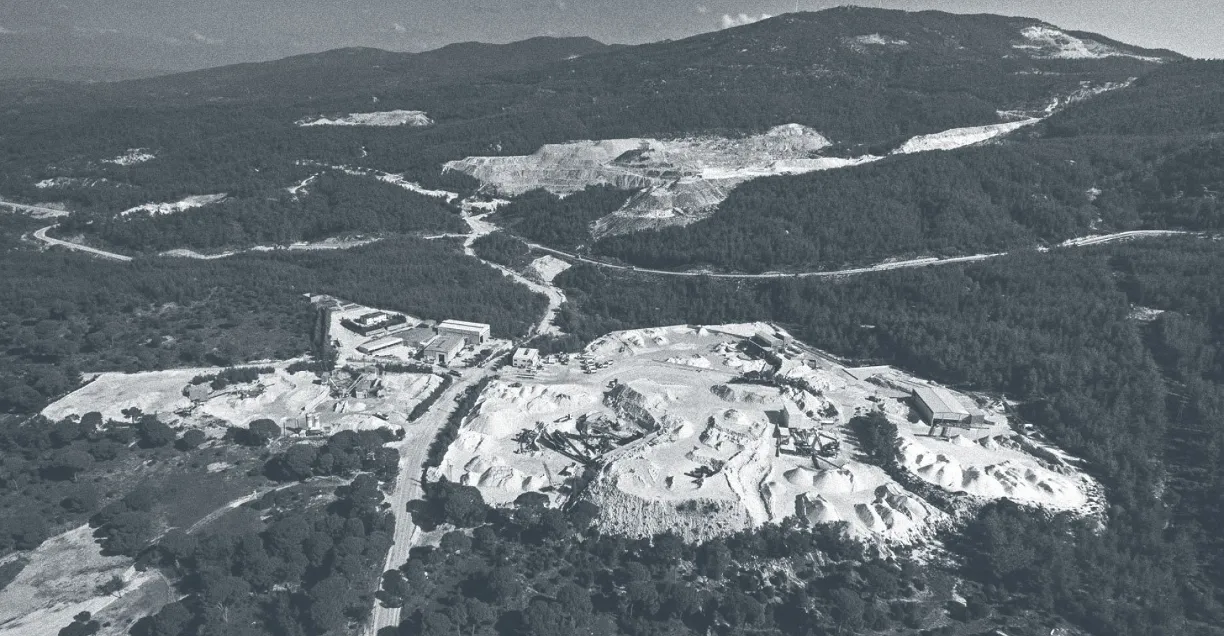

Blind Spots in Remote Sites

With multiple remote quarry sites and processing plants, Kaltun struggled to get real-time data on crusher utilization and weighbridge transactions. Manual reporting caused delays in production planning.

- check_circle Rugged Edge Nodes: Deployed IP65 nodes to collect data from PLCs and weighbridges in dusty environments.

- check_circle Wireless Backhaul: Used long-range wireless links to centralize data from scattered crushers.

- check_circle ERP Integration: Automated flow of production tons directly into the central ERP system.

Operational Impact

Drive efficiency from the pit to the stockpile.

Optimize feed rates and reduce blockage downtime with amp-based control.

Reduce idle time on haul trucks and excavators via fleet tracking.

Automated weighbridge integration eliminates manual ticket logging fallibility.

Mining FAQ

Common questions from site managers and automation engineers.

Can Proxus run on sites without internet connection? expand_more

Yes. Our Edge Nodes store up to 30 days of data locally. They can operate fully autonomously to run safety rules and PLC setpoints, syncing with the cloud only when backhaul (satellite/LTE) is available.

Do you support legacy weighbridges? expand_more

Yes. We connect to serial (RS-232/485) ports on weighbridge indicators to digitize ticket data, automatically associating weights with truck IDs and material types.

How do you handle harsh environmental conditions? expand_more

Our Edge software runs on ruggedized industrial PCs (IP67 rated, wide temperature range) designed to withstand dust, vibration, and extreme heat common in mining operations.

Optimize Your Mine

Rugged, reliable, and real-time. Connect your site today.