Predictive Maintenance

for Industrial IoT

Detect failures before they stop production. Proxus unifies vibration, temperature, and runtime data so you can build rules, detect anomalies, and trigger actions in real time.

What makes it work

Proxus connects sensor data, normalizes tags, and evaluates rules at the edge. You get fast detection, clean data models, and reliable alerts without rebuilding integrations for every plant.

- check_circle Live connectivity from PLCs and sensors using industrial protocols.

- check_circle UNS tag model to standardize assets with Unified Namespace.

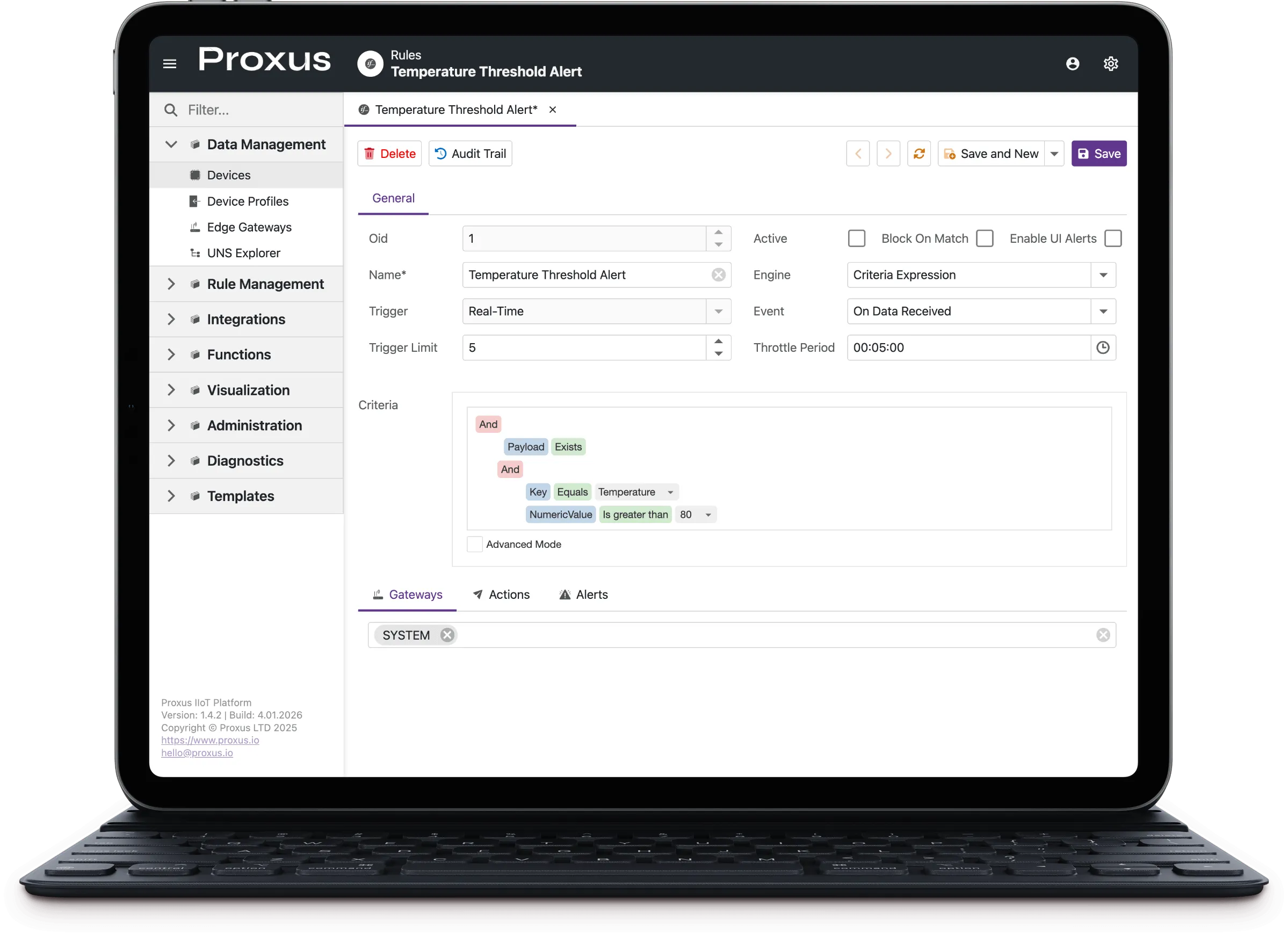

- check_circle Edge rules using the rule engine for alerts and automation.

Typical signals

How it works

Connect assets

Onboard PLCs, drives, and sensors once and reuse templates across sites.

Normalize tags

Map signals to a consistent UNS model for analytics and dashboards.

Trigger actions

Run rules at the edge, notify teams, and open tickets automatically.

FAQ

Common questions about predictive maintenance rollouts.

No. Start with rules and thresholds, then add ML later using the same data model.

Yes. Proxus evaluates rules on gateways so alerts fire even when the network is down.

Export alerts to CMMS, ERP, or BI using IT/OT connectors.

Reduce downtime before it starts

See how Proxus brings predictive maintenance to your existing assets.